Retailers across the globe struggle with overstock and understock every day. If they buy too much, they waste money on storage and risk products expiring. If they buy too little, they lose sales and send customers elsewhere. According to IHL Group, these problems add up to over $1 trillion in lost revenue each year. That’s massive.

Luckily, AI in supply chain helps solve this balancing act. It takes the guesswork out of ordering and replaces it with precise, real-time decisions based on data from many sources.

In this article, we’ll explore how artificial intelligence in supply chain management flips old methods on their head, turning reactive processes into proactive ones. You’ll also learn how supply chain AI tools on AWS can keep your inventory at just the right level. No more worrying about leftover stock or losing sales to empty shelves.

We’ll walk through why old approaches no longer work and reveal how AI in supply chain management helps. Real-life examples will show the benefits of modern methods and how you can analyze them to make better choices. Stick around to see how you can leverage AI for supply chain success. By the end, you’ll understand why smart retailers adopt AI in supply chain and logistics for fast, data-driven decisions.

Why inventory is the retail balancing act

Inventory management is a tightrope walk. Lean too far to one side, and you have too many goods collecting dust. Lean too far the other way, and you disappoint customers who can’t get what they need. Let’s see why mastering this balance sets successful retailers apart.

Inventory: Balancing between waste from surplus and loss from shortage

Excess inventory leads to high storage costs and can create waste. Foods expire, electronics become outdated, and styles go out of fashion. The extra goods take up warehouse space, run the risk of damage, and often need markdowns to clear them out. That’s a direct hit to your market margin.

But shortages can be just as damaging. When customers can’t find what they want, they leave and might not return. This causes lost revenue and chips away at brand loyalty. In many cases, they’ll spread the word about your empty shelves, hurting your image. It’s a dangerous cycle that can scare off even loyal shoppers.

Stockouts cause billions in lost revenue and broken customer trust

Think about how you shop. If you go to your favorite store and it’s out of the product you need, you may look elsewhere. A report from the Grocery Manufacturers Association says that over 70% of shoppers will switch to a competing brand or store after a few stockouts. They won’t wait around. Over time, you lose significant sales and damage your standing in the market.

One simple example: A new brand goes viral on social media. Demand surges, yet the store doesn’t stock up. People show up, find empty shelves, and flood the comments sections with complaints. These posts can reach thousands of potential customers, making matters worse. Once these shoppers form a negative impression, it’s tough to win them back.

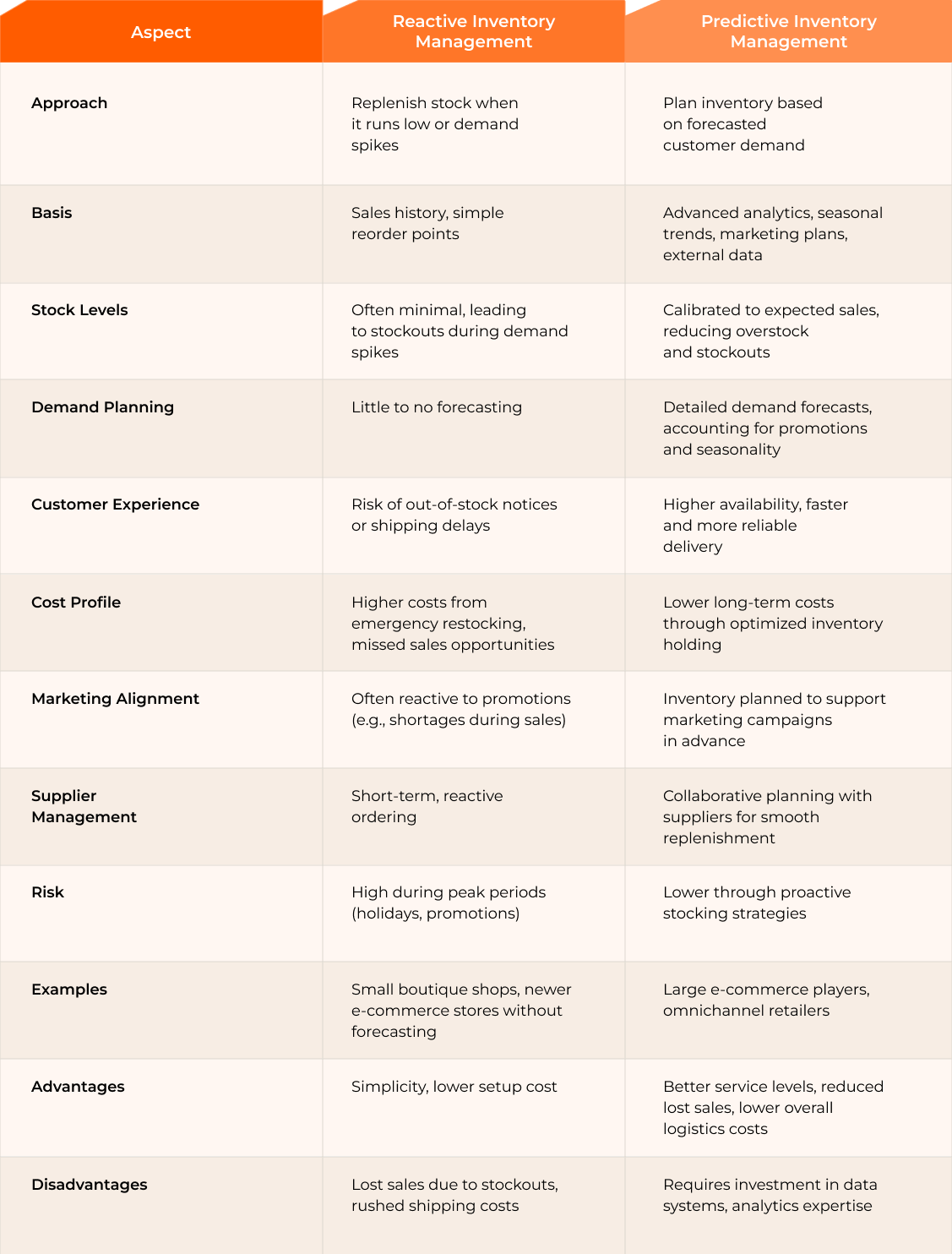

AI transforms inventory from reactive to predictive

In traditional systems, you wait for something to happen, like a surge in sales, and then respond. By that point, you might have lost sales or wasted money on rushed deliveries. AI supply chain planning turns your process from reactive to predictive. It studies trends to forecast what’s coming and adjusts your stock levels ahead of time.

Consider a sudden spike in snack sales because an influencer shares a video. A reactive approach might learn about this too late, leading to stockouts. An AI-driven approach, however, can catch the early rise in online chatter and place an additional order. This impact is huge. With AI in supply chain, you stay a step ahead and avoid those dreaded empty shelves.

Cloud-based AI enables real-time, scalable, data-driven supply chain decisions

Running AI on the cloud, such as AWS, allows you to scale up or down with ease. Your system can process millions of signals at once – from point-of-sale data to weather reports – in near real time. This speed and agility help you decide when and how much to reorder. They also let you reroute goods to match sudden changes in demand.

In effect, AI in supply chain and logistics gives you a living, breathing view of your operation. You see changes as they happen and can adjust without waiting for delayed data. That means fewer missed sales, more efficient shipments, and a big boost in customer satisfaction.

Traditional inventory management: Why it’s broken

Old inventory methods rely on spreadsheets, guesswork, and manual labor. While these worked when markets moved at a slower pace, they don’t cut it now. Trends shift overnight, and consumer preferences can change on a dime.

Forecasting based on historical sales alone is no longer sufficient

Drawing lines from past data helps if the future looks the same as yesterday. But we’ve seen how unpredictable things can be. Economic events, viral online trends, and sudden shipping issues disrupt patterns. If you only look backward, you’ll miss new developments.

This is how artificial intelligence is used in supply chains and stands out: it includes external cues. AI solutions can factor in weather, social media chatter, or even local events like concerts. With these insights, the system anticipates needs before they show up on your balance sheet.

Manual planning is time-consuming, error-prone, and hard to scale

When you rely on humans entering figures by hand, you risk mistakes. People forget to update a cell or type in the wrong number. These errors can grow with each new line of data. That leads to big inaccuracies in reorder points or item counts.

Manual systems also break under pressure. A sudden jump in SKUs or a new sales channel can overwhelm your staff. You end up running behind real-time events, and by the time you catch up, customers may already be looking elsewhere.

Siloed systems and batch processes delay reaction time

Many stores store their inventory data in one place, while their shipping details live in another. Meanwhile, marketing runs in a separate system. This siloed setup makes it tough to completely understand what’s happening. Worse yet, some stores process data only once a day. That means you might be looking at stale numbers while real events race ahead.

AI for supply chain thrives on live, connected systems. It ties everything together so data moves freely between channels. If an item sells out in one store, the system updates your central platform right away. Then it either reorders stock or reroutes extra units from another location.

Inability to handle external factors

Standard spreadsheets can’t factor in wild swings like a sudden social media craze or a storm that shuts down roads. By the time you see the effect, you might have a backlog of late deliveries or a swarm of angry customers. AI in supply chain management fixes that. It reads outside data sources, spots what might be coming, and raises flags in time for you to respond.

_______________________________________________________________________

Tired of running out of popular items or drowning in surplus stock?

See how AWS-based AI in supply chain can give you the potential to stay on top of trends. Contact us to learn more about real-time insights that can transform your inventory game.

_______________________________________________________________________

What makes inventory “smart” with cloud AI

So, how do we get from manual guesswork to a modern, predictive system? AI in supply chain relies on several technologies that track data, learn patterns, and adapt in real time. Here are the core components.

Predictive demand forecasting with time-series and regression models

Cloud AI services use models like ARIMA for time-series data, XGBoost for boosted decision trees, or Facebook Prophet for seasonal variations. These models cut through big data sets to see short- and long-term trends. They also adapt when new signals appear, so they’re always improving.

When you tap into AI supply chain planning, you don’t forecast once a month. You do it daily or even hourly. This helps you spot dips or spikes in near real time, which leads to fewer surpluses or shortages.

Real-time tracking of stock levels and supply chain events

IoT devices, sensors, and APIs can update your inventory status minute by minute. This gives you a constant feed of what’s happening at each step, from factory to store shelf. Because you know your exact stock levels, you can decide when to order more or move items to a new location.

If a supplier runs late, you know right away. Instead of waiting until the day the shipment was due, you can pivot as soon as your system detects a delay. That faster response protects you from bigger problems down the road.

Dynamic restocking and auto-reordering based on machine learning triggers

Traditional tools say, “When you have X units left, reorder Y.” That’s static and doesn’t fit a world where conditions change hour by hour. AI in supply chain management reorders when it sees real patterns, like a demand spike or a promotional event that will soon drive sales. It’s a fluid approach that shrinks your risk of stockouts.

For instance, if your best-selling item sees a surge in interest after a social media post, the system flags it. It might reorder earlier than usual, so you stay fully stocked. By the time your competitors realize a trend is happening, you’re already prepared.

External signal integration: Market trends, seasonality, and even social sentiment

Modern artificial intelligence in supply chain market solutions read more than your internal data. They also gather data from sources like Google Trends, local weather, or social media posts. If a holiday is coming or an influencer mentions your product, your AI system can forecast a jump. It then adjusts your supply and distribution to meet that demand.

This type of 360-degree view stands out. Instead of guessing what the world might throw at you, your supply chain keeps tabs on real signals. It’s always ready to optimize based on the full picture.

_______________________________________________________________________

For a closer look at solutions built with AWS generative AI services, see IT-Magic’s AWS Generative AI Services page.

_______________________________________________________________________

Key use cases for AI in inventory and supply chain optimization

AI in supply chain helps in many ways. Whether you’re a small operation or a massive retailer, these use cases can level up your approach.

SKU-level demand forecasting for replenishment planning

Not all products sell at the same pace. Some products might move faster in certain regions or at certain times of the year. With artificial intelligence for supply chain, you can forecast demand for each SKU. That means you stock the right amount of each product in every location, cutting extra overhead and slashing out-of-stocks.

Dynamic safety stock calculations based on supply variability

Some suppliers are rock-solid, delivering on time, every time. Others face hiccups due to unpredictable routes or shipping constraints. AI for supply chain solution factors these risks into your safety stock. Instead of setting one blanket buffer across your entire product line, you create dynamic levels based on each supplier’s reliability.

Automated replenishment via real-time thresholds

When you rely on real-time data, you can automate the reorder process. If your sales velocity for a product is higher than usual, your system triggers a new order on the spot. This cuts manual work and ensures that your shelves or website stay stocked. It also prevents over-ordering items that aren’t moving.

Warehouse distribution optimization using predictive analytics

Moving goods among warehouses can be complex. Supply chain management AI makes those moves more precise. It uses predictive analytics to see which regions will need which items and when. Then it directs stock to the right place, reducing shipping time and last-minute transfers. You save on freight costs and keep customers happy with faster deliveries.

Promotion-aware planning

Sales, holiday discounts, or influencer campaigns can drive sudden demand spikes. Without AI in supply chain, it’s guesswork. With AI, your system sees these events coming because it’s connected to marketing schedules, social media, or e-commerce data. It bumps up reorders ahead of time so you don’t run out at peak moments. Once the promotion ends, it scales back to avoid leftover stock.

Multi-location inventory balancing to reduce shipping time and cost

If you have several warehouses or stores, you need to coordinate stock levels. AI in supply chain and logistics can see your entire network and direct goods where they’re needed. If one location has extra items that another store needs, the system arranges a transfer. This keeps each location lean and reduces the need for express shipping later.

AWS tools that power smart inventory

To unlock all these benefits, you need a strong technology platform. AWS offers many solutions to run real-time analytics and machine learning for inventory optimization.

Amazon Forecast

Amazon Forecast automates machine learning for demand forecasting. You give it data, like sales numbers and promotional calendars, and it chooses the right model (ARIMA, DeepAR+, or something else). It’s serverless, so you don’t have to manage infrastructure. You can tailor it to your needs with extra data, such as web traffic or store foot traffic.

Key highlights:

- Ready-made ML models for quick deployment

- Scalable, so you pay for what you use

- Easy to import data from your existing systems

Amazon SageMaker

SageMaker helps you build and deploy custom machine learning models. It’s great if you need special algorithms or more control than a managed service can provide. For AI supply chain planning, you might create your own forecasts, do anomaly detection, or simulate supply chain changes.

Common use cases:

- Custom neural networks for unusual demand patterns

- Scenario testing to see what happens with different reorder strategies

- Prototyping advanced supply chain ideas

AWS Lambda & EventBridge

AWS Lambda is a serverless compute service. It runs code in response to events without the need for your servers. EventBridge routes events to the right place. Together, they trigger real-time actions when certain conditions occur. For example, if a stock level drops below a set threshold, EventBridge passes that alert to Lambda. Lambda checks your AI model’s forecast and, if needed, places an order.

Typical steps:

- A store reports a large sales uptick via an event.

- EventBridge sends this event to a Lambda function.

- Lambda calls SageMaker or Forecast to see if reordering is required.

- The system issues a new purchase order or reallocates stock.

Amazon Kinesis

Kinesis handles streaming data in real time. If you have thousands of sales per minute, Kinesis can take that feed, process it, and pass it to your ML models. This helps with immediate reaction. If an item sells faster than usual, the system notices. Then it updates your dashboards and triggers follow-up steps, like reordering or shifting stock between regions.

Amazon S3 / Redshift / Glue

Amazon S3 holds raw or structured data from logs and sensors. Acts as a data lake.

AWS Glue cleans and organizes data so it’s consistent and ready for analysis.

Amazon Redshift is a high-performance data warehouse. Great for running complex queries over big datasets.

When combined, these tools give you a strong data pipeline. You can store raw data, transform it to make it useful, and then run queries to extract insights for your inventory operations.

QuickSight

QuickSight is AWS’s business intelligence tool. You can build live dashboards that show your stock levels, shipping statuses, or forecast accuracy. It connects to data in Redshift, S3, or other AWS services, letting you turn raw numbers into clear visuals. This helps everyone – from planners to executives – see what’s happening and make faster decisions.

Business value of cloud AI for supply chains

Upgrading your inventory system with AI delivers real, measurable results. Here are the main wins you can expect from AI in supply chain.

Reduced lost sales due to better product availability

When a product is always on hand, shoppers become loyal. Many AI-driven retailers report a big drop in stockouts – some see reductions of 30% or more. That translates to direct gains in revenue because you aren’t missing sales opportunities. You also strengthen customer trust and increase return visits.

Lower operational costs

Poor inventory practices waste money in several ways. You spend on unneeded storage, emergency shipping, and extra labor to fix errors. By using AI for supply chain optimization, you cut these hidden costs. You also reduce the amount of capital tied up in extra goods that may not sell right away.

Improved planning cycles

Instead of planning a few times each year, you do continuous forecasting. That means your figures are always current, so you’re ready when the market shifts. If a product’s popularity fades, your AI system will notice and adjust. You don’t have to wait for the end of the quarter to make changes.

Better customer satisfaction with reliable fulfillment

Customers expect stores to have products in stock or deliver them fast. Using AI and supply chain management helps meet these expectations. You have fewer backorders, faster shipping, and fewer last-minute changes. The result is happier shoppers who leave higher ratings and come back more often.

Real-time agility: Respond to demand changes instantly

A single TikTok post can drive sales of a product overnight. If you rely on manual processes, you react too slowly and miss out. AI in supply chain tracks these trends in real time. As soon as sales or online mentions spike, your system updates the forecast. That real-time agility is what sets modern retailers apart from the pack.

Risks and how to mitigate them

Adopting AI in supply chain has big upsides, but you must watch for pitfalls. Below are key concerns and how to handle them.

Data quality challenges

Your models are only good if the data they receive is good too. If your feeds contain errors or incomplete records, your forecasts will be off. To fix this, set up quality checks and cleaning processes. Tools like AWS Glue automate much of this, so you can trust your numbers.

Over-reliance on models without business logic guardrails

AI models see patterns, but they might not grasp all your business rules. For example, they might cut safety stock below your comfort level to save costs. You need to add guardrails. Tell the system, “Never drop below X units,” or “Always hold Y amount of essential goods.” This hybrid approach blends ML insights with your real-world know-how.

Model drift and the need for retraining

Markets change. Supplier performance shifts. Consumer tastes evolve. Over time, these shifts can lower your model’s accuracy, known as model drift. Schedule regular retraining. Watch for changes in forecast accuracy. If your predictions start missing the mark, it’s time to refresh the model with new data.

Change management: Aligning operations and IT teams

AI in supply chain isn’t just about technology; it’s about people. Your team must adapt to new workflows and trust data-driven choices. This might require staff training or new roles. Make sure everyone sees the value of AI so they’re motivated to use it. That cultural shift can make or break your success.

Common Risks vs. Mitigation

| Risk | Mitigation |

| Low-quality data feeds | Use ETL pipelines and validation (AWS Glue) |

| Over-reliance on AI without logic guardrails | Combine ML with clear business rules |

| Model drift | Retrain models on a set schedule |

| Poor team alignment | Provide training and leadership buy-in |

Final thoughts: From guesswork to predictive precision

Inventory optimization goes beyond spreadsheets with AI power. If you rely on old methods or basic software, you may struggle to keep up. Data pours in from all sides, and consumer preferences change fast. AI in supply chain lets you connect the dots and see patterns that manual approaches miss. The outcome is fewer errors, better stock availability, and a more stable operation.

Boost margins and cut waste with AWS-driven fulfillment

Throughout this article, we’ve seen how artificial intelligence in logistics and supply chain slashes errors and speeds up decisions. Integrate that with the flexibility of the AWS cloud, and you have a formula for success. You’ll waste less, keep shelves stocked, and maintain loyal customers. That’s a big win for your bottom line and your brand reputation.

End stockouts and optimize your supply chain today!

Take the next step with AWS-driven AI solutions. Book a call with our experts, and let’s craft a future-proof path to efficient, reliable operations.

FAQ

How does AI handle supply chain disruptions in real time?

AI for supply chain optimization uses continuous data streams like Amazon Kinesis. It analyzes signals the moment they appear. If there’s a delay or a sudden demand spike, your system pivots. It may order more stock, reroute deliveries, or notify staff before a small problem becomes a crisis.

How fast can I see ROI after implementing AI in inventory management?

Many retailers notice real gains in three to six months. During that time, you’ll set up data pipelines, train initial models, and refine processes. By catching stockouts sooner and cutting down on over-ordering, you can free up capital and start seeing solid returns.

What are the risks of using AI for inventory, and how can I avoid them?

Main risks include bad data quality, failing to retrain models, and ignoring human insight. You can dodge these issues by cleaning your data, setting regular model updates, and applying business rules as guardrails. A pilot phase also helps you spot trouble areas early, so you can fix them before launching at scale.