We’ve all been there. You find the perfect item online. You’re excited. You place it in your cart, prepared to make the purchase. Then those dreaded words appear: “out of stock.” You get frustrated and disappointed. For a business, that moment is more than just one lost sale. It’s a broken promise to your customer. Today, when another shop is just a click away, stockouts can kill your brand. But what if you could know what your customers wanted, even before they did? This isn’t a dream. It’s the power of AI inventory management.

For too long, retailers have been stuck in a guessing game, trying to avoid having too much stock or too little. The old ways of looking at last year’s sales just don’t work anymore. Customers move too fast. That’s why smart retailers are now using AI for inventory management. It helps them switch from reacting to problems to predicting the future. By using real-time data, smart algorithms, and automation, businesses are cutting down on stockouts and changing how their operations work. Let’s dive into how AI-based inventory management, paired with powerful cloud tools like AWS, helps keep shelves stocked, reduces waste, and makes sure products are ready for your customers.

Why stockouts still hurt retail in 2025

You’d think we’d have solved empty shelves by now. But even in 2025, stockouts are a huge headache for retailers. It doesn’t matter how great your marketing is if the product isn’t there when someone wants to buy it. Here’s the deal on why this still hurts so much.

Stockouts are a major cause of lost sales, poor customer experience, and churn

An unavailable product is a roadblock for a ready-to-buy customer. It’s a huge problem. In fact, the total cost of stockouts and overstocks was a massive $1.77 trillion in 2023, according to an IHL Group study. A big piece of that comes directly from items being unavailable.

But the real consequences go far beyond a single lost sale. A customer who can’t find what they want gets frustrated. If it happens again, they’ll think your brand is unreliable. They will go to a competitor. With e-commerce and same-day delivery as the new normal, the stakes are higher than ever. If a customer has a bad experience, they are very unlikely to come back.

In a hypercompetitive market, availability can be the differentiator

When customers have endless choices, having the product ready to go makes you stand out. People today want things instantly. The retailers who always have their products in stock are the ones who win.

Think about Amazon or Walmart. A huge part of their success is their ability to manage inventory. They use smart AI and inventory management to guess what people will buy. This means their physical and digital shelves are almost always full. This makes customers see them as reliable, building loyalty that lasts.

AI in cloud-native infrastructure: Shifting retail to predictive inventory

This is where things get interesting. We’re moving from reacting to sales to predicting them.

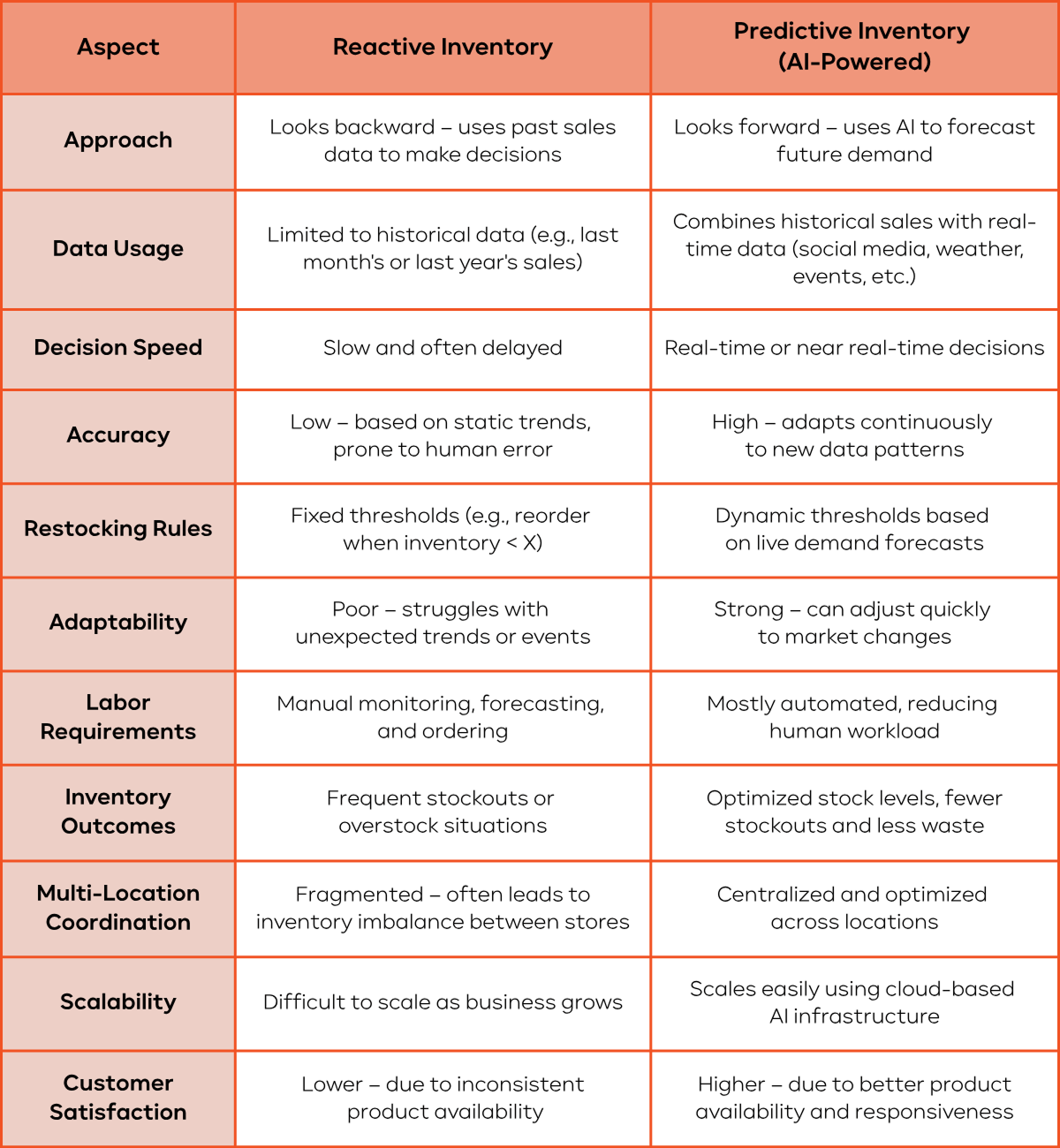

- Reactive inventory is the old way. You look at last month’s numbers and order more. It’s simple but slow and often wrong. This leads to a cycle of being out of stock, then having too much.

- Predictive inventory is the new way. You use inventory management AI to look at tons of data. This covers previous sales, weather conditions, trending topics on social media, and nearby events. It helps you predict what people will want with amazing accuracy.

You no longer need a room full of servers to do this. With cloud platforms like Amazon Web Services, any business can use these powerful AI tools. It lets you turn your inventory systems from a simple list into a tool that knows what your customers want next.

_______________________________________________________________________

Tired of playing catch-up with your inventory?

If you want to see how using AI for inventory management can change your operations, we can help. Our team at IT-Magic builds smart AI solutions on AWS that grow with your business.

_______________________________________________________________________

The true cost of stockouts (and overstock)

A stockout costs more than just one sale. The damage spreads. It hits your profits, your brand’s reputation, and how smoothly your business runs. And its twin problem, overstock, quietly drains your money in the background.

Direct revenue loss from missed sales

This one is easy to see. An out-of-stock item means a lost sale. During the holidays or a big promotion, these lost sales add up fast. They can cost businesses millions. Imagine a popular toy being gone in December. The financial hit is direct and painful.

Long-term damage to customer loyalty and trust

This cost is quieter but much worse. One stockout might be okay. But if it keeps happening, customers lose trust. They’ll stop checking your store and go somewhere else. You lose that customer’s business for life. Winning them back costs far more than it would have to just keep them happy.

Emergency fulfillment costs or markdowns

When you run out of something, you rush to get more. This rush costs money. You might have to:

- Pay for expensive express shipping.

- Move stock from one store to another at a high cost.

- Waste your team’s time calming down unhappy customers.

On the other hand, having too much stock is also a money pit. It holds back resources you could invest in growth. You pay more for storage. And you often have to sell the extra products at a big discount, which kills your profit margins.

Inventory imbalance: overstocking in one location, shortage in another

Retailers with multiple locations often face this problem. While one store has empty shelves, another has more than it needs. This happens when you can’t see all your inventory in one place. AI inventory management fixes this. It provides complete visibility into your inventory across all locations. It can even suggest moving products between stores to meet local demand. This prevents stockouts in one place and overstock in another.

The core of AI-powered inventory management

So how does inventory AI pull this off? It’s not magic. It’s about using smart computer programs and live data to make better guesses. These systems learn over time, finding insights that old methods could never see. Here’s a look at the main parts.

Predictive demand forecasting at SKU, location, and category level

This is the brain of AI inventory management. Instead of using simple averages, AI models look at huge amounts of data to predict demand for each specific item. It can forecast how many units of a single product (SKU) you’ll need, at which store, and for a certain period.

These models look at factors that old systems miss:

- Seasons and trends: They learn patterns for things like holidays or back-to-school shopping.

- Local factors: They can look at local events or even weather forecasts that might change what people buy.

- Customer behavior: They track what people are searching for online or talking about on social media.

This gives you a forecast that is much more accurate, so you can stock what your customers actually want.

Dynamic restocking thresholds adjusted by real-time data

Old inventory systems use fixed rules, like “order more when you have less than 50 left.” This is too rigid for the real world.

AI for inventory management uses dynamic or changing rules. With real-time data inputs, the system fine-tunes your reorder points. If a product suddenly goes viral online, the AI can raise the reorder point to avoid a stockout. If sales slow down, it can lower it to prevent overstock. This allows for an instant response based on market activity.

Automated replenishment and purchase order generation

Creating purchase orders by hand is slow and full of chances for errors. AI inventory management automates this job. When stock levels hit the AI’s smart trigger point, it can automatically create a purchase order and send it to your supplier.

This brings big benefits:

- Speed: Orders go out instantly, which means you get your products faster.

- Accuracy: No more typos or mistakes that lead to wrong orders.

- Efficiency: Your team is freed up from boring paperwork. They can now work on more important things, like building good relationships with suppliers.

AI-driven product lifecycle planning

Not all products sell forever. AI inventory management helps you plan for every stage of a product’s life.

- New products: For new items with no sales history, the AI looks at similar products to make an educated guess on demand.

- Peak and decline: The system can tell you when a product’s popularity is fading.

- Markdowns: By predicting when a product is near the end of its life, the AI can suggest the best time to put it on sale to clear it out. This helps you get rid of slow-moving items with less of a loss.

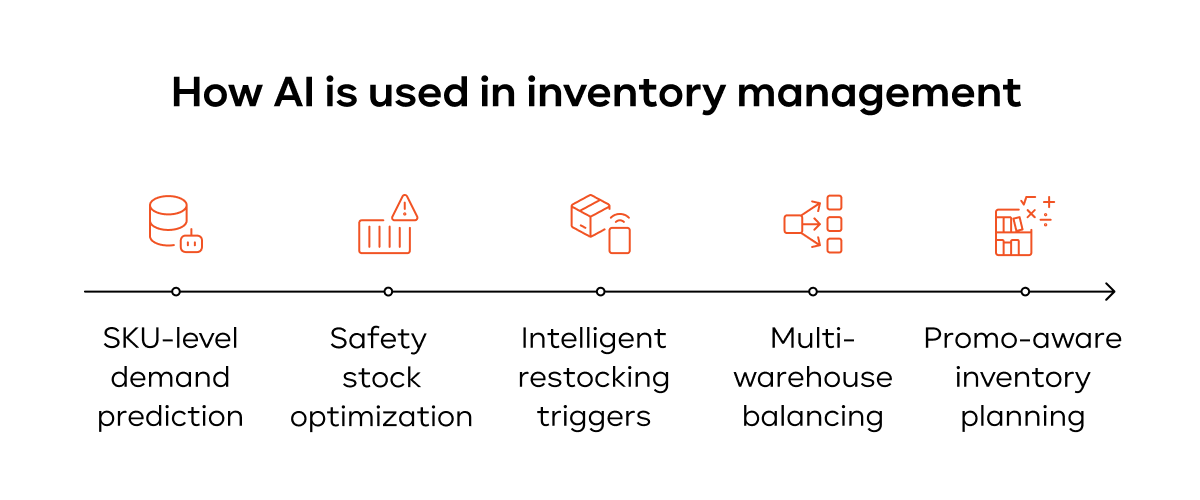

Key AI use cases for reducing stockouts

Implementing AI inventory management covers several vital areas that, together, enhance your supply chain. Take a look at how retailers are successfully using it to prevent stockouts.

SKU-level demand prediction

This is the foundation. Machine learning lets you predict demand for every product in your catalog. This lets you order with great precision. You’ll have enough of your bestsellers without over-ordering the slow movers. This fine-grained detail is key to keeping your shelves full and sales high.

Safety stock optimization

Safety stock is an extra inventory you can rely on in case of unforeseen demand spikes or supply delays. The old way was to use a fixed number, which often meant you held way too much stock, tying up money. AI inventory optimization creates smart buffers instead. The AI figures out the ideal amount of safety stock for each product based on sales predictability. This cuts down on how much cash is tied up in inventory without raising your risk of stockouts.

Intelligent restocking triggers

As we said before, inventory AI uses smart triggers instead of fixed ones. These triggers are fed by live data from many places:

- Your cash registers (POS data)

- Your main business software (ERP systems)

- External data, like social media trends or local events

By watching how fast things are selling, the AI sets smarter triggers that get ahead of demand.

Multi-warehouse balancing

AI and inventory management are game-changers for multi-warehouse retailers. The system gives you one clear view of stock across your whole network. If it sees one area selling a lot of an item while another has too much, it can suggest a transfer. This smart balancing prevents stockouts where you need items most.

Promo-aware inventory planning

Customer demand can spike quickly during sales and promotions. AI-based inventory management systems are built to plan for this. They look at data from past promotions to predict how much a new sale will boost demand. This helps you order the right amount of stock to be ready for the rush, without getting stuck with leftovers.

AWS services that power smart inventory

To build a smart AI inventory management system, you need a strong and flexible tech foundation. AWS offers a set of tools that are perfect for retail. They give you what you need to handle huge amounts of data, train smart models, and get real-time answers.

Amazon Forecast

Think of Amazon Forecast as a crystal ball for your sales. It’s a tool that uses machine learning to predict future demand. You ca use it without being an AI specialist. Just feed it your past sales data, and it gets to work. It can even help with new products by looking at similar items to make a first guess.

Amazon SageMaker

For businesses that want to build their own custom solutions, Amazon SageMaker is a complete toolbox. It lets your team build, train, and launch machine learning models of any size. You can create your own forecasting tools or design unique AI inventory optimization rules that fit your business perfectly.

AWS Lambda & EventBridge

A modern inventory system needs to act fast. AWS Lambda lets you run code that triggers automatically based on events, like a sale being made. You don’t have to worry about servers. Amazon EventBridge helps connect all your different apps and data sources, so these automated processes run smoothly.

Amazon Kinesis / IoT Core

Your inventory AI relies on live data to make informed decisions. With Amazon Kinesis you can gather and analyze real-time data streams. This could be sales info coming from all your stores or location data from delivery trucks. This live feed enables you to make make faster and smarter restocking choices.

DynamoDB / S3 / Redshift

Data is the fuel for AI. AWS has a range of storage options built for speed and size:

- Amazon S3: A great place to store all your raw data in what’s called a “data lake.” It’s secure and can handle almost any amount of information.

- Amazon DynamoDB: A super-fast database that’s perfect for keeping track of real-time inventory levels.

- Amazon Redshift: A powerful tool for analyzing huge datasets. It’s what you use to find deep insights and train your AI models.

Amazon QuickSight

All this great data is only useful if you can understand it. Amazon QuickSight turns your data into easy-to-read charts and dashboards. Your business and tech teams can use it to track goals, see forecasts, and get alerts on their phones or computers.

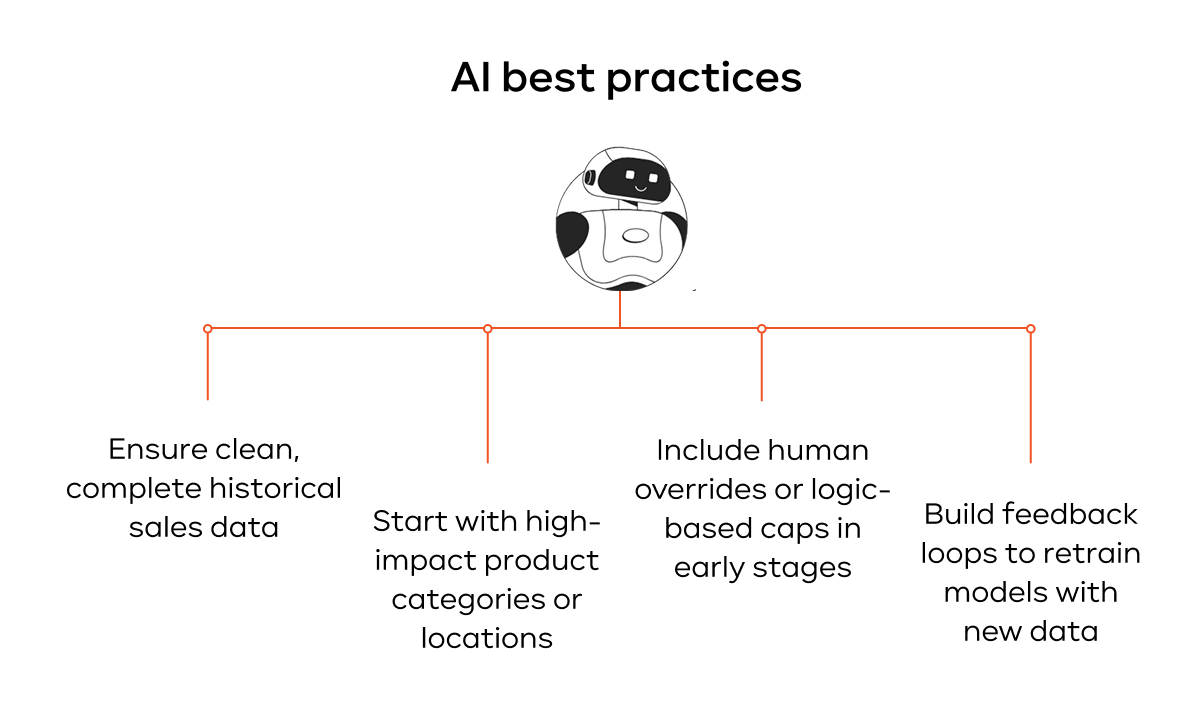

Best practices for successful AI-driven inventory management

Switching to an AI inventory management system is more than a tech upgrade. It’s a new way of doing business. To succeed, you need a smart plan for your data, your rollout, and your team.

Ensure clean, complete historical sales data

Your AI is only as effective as the data quality behind it. It’s the old rule of ‘garbage in, garbage out.’ Before you start, you must clean up your sales history.

Good data should be:

- Clean: No mistakes or duplicate entries.

- Labeled: Tagged with the right product number, store, and date.

- Structured: Organized in a way that’s easy for a computer to read.

Taking time to prepare your data first will make your AI’s predictions much more accurate.

Start with high-impact product categories or locations

Don’t try to switch your whole company over to AI at once. That’s a recipe for failure. Instead, start small with a pilot project. Pick an area where you can get a big win quickly. This could be:

- Your bestselling items that often run out.

- A product group with very unpredictable sales.

- One area or a few of your top-performing locations.

A successful pilot will prove the value of AI and get everyone on board for a wider rollout.

Include human overrides or logic-based caps in early stages

The idea of an AI making big decisions can be scary. To build trust, let your team have the final say at first. This is called a “human-in-the-loop” approach. It lets a manager review and approve the AI’s suggestions. Hard rules, like limiting orders to 500 units without approval, give you some protection while your team adapts to the new system.

Build feedback loops to retrain models with new data

The market is always changing. An AI model trained on last year’s data will get stale over time. To fix this, you need a process to keep your models fresh.

- Monitor: Keep an eye on how well your model is predicting sales.

- Retrain: Set up an automatic process to retrain your model with new data every week or month.

- Check: Have a person review the retrained model to make sure it still makes sense for the business.

Challenges and how to solve them

Moving to an AI-driven system can feel intimidating. Many businesses worry about the challenges, from messy data to high costs. But these problems can be fixed with a solid plan.

Cold-start problem: new SKUs or suppliers

How do you predict sales for a brand-new product? This is a common challenge.

- The solution: An AI system can handle this by using AI for inventory management tricks. It analyzes the new item’s attributes, such as price or category, and identifies similar products in your catalog. It then uses the sales history of those “look-alike” items to make a starting forecast. Over time, as the new product sells, the AI uses that new data to get even smarter.

Data silos between ERP, POS, and e-commerce systems

In many companies, important data is stuck in different systems that don’t talk to each other. Your sales system, your website, and your warehouse software all have their own separate information.

- The solution: You need to bring it all together. The best way is to create a central “data lake” using a tool like AWS S3. Then, a service like AWS Glue can pull the data from all your different systems, clean it up, and put it in one place. This breaks down the walls between your data and gives your AI the clean, unified information it needs.

Over-reliance on AI vs. business logic

You can’t let an AI run the whole show without any oversight. An AI might suggest something that makes sense mathematically but is bad for the business.

- The solution: The best systems mix AI smarts with human knowledge. It’s important to set business rules that the AI has to follow. For example, you might set a rule that you never want to hold more than a certain amount of a large, low-profit item, even if the AI predicts more sales. Combining AI insights with your team’s experience creates a system that is both smart and practical.

Model drift and retraining frequency – use MLOps practices

An AI model is not a one-and-done project. As trends change, a model trained on old data will become less accurate. This is called model drift.

- The solution: You need a solid MLOps (Machine Learning Operations) plan. This means having an automated system to check your model’s performance, retrain it regularly with fresh data, and track different versions. This disciplined approach keeps your forecasts accurate and useful for the long haul.

Final thoughts: Predictive inventory is no longer optional

In today’s retail world, you have to be fast and focused on the customer. Sticking with old, reactive ways of managing inventory just won’t cut it anymore. The ability to predict what’s coming and have your products ready is what separates the winners from everyone else. AI inventory management has gone from optional to essential.

AI empowers modern retail with agility and revenue foresight

By moving from reacting to predicting, artificial intelligence inventory management gives retailers the speed they need to keep up. It helps them spot trends, react to demand instantly, and make smarter, data-driven choices. The results are clear: fewer stockouts, happier customers, less waste, and huge savings. This isn’t just about cutting costs. It’s about building a stronger, smarter, and more profitable business.

Achieve inventory excellence with secure, scalable AWS solutions from IT-Magic

Starting your journey with AI inventory management requires the right partner. At IT-Magic, we build secure and powerful retail AI solutions on the AWS cloud. We know the retail industry and have the tech skills to help you pull your data together, build the right models, and launch your new system. We want to give your business the tools it needs to master its inventory.

Reduce your stockouts - book a discovery call to start your AI journey

Ready to make empty shelves a thing of the past? We can show you how. Let us help you launch a pilot project and see real results in a short time.

FAQ

Can AI forecast demand for new products with no sales history?

Yes. We call this the “cold-start problem.” AI for inventory management solves it by looking at the features of the new product, like its price or category. It then finds similar items you already sell and uses their sales history to make a good first guess. Once the new product starts selling, the AI uses that new data to make its forecasts even better.

What data do I need to get started with AI inventory forecasting?

To get started with AI inventory management and forecasting, you’ll need a few key things:

- Historical sales data: This is the most important. The more detailed, the better.

- Product info: Details about each product, like its brand and price.

- Promo data: A list of your past and upcoming sales or promotions.

- Seasonality data: Information about holidays or other seasonal events.

- Location data: Info on your different stores and warehouses.

The cleaner your data is, the better your results will be.

What if I have data in multiple systems that don’t talk to each other?

That’s a very common issue. The solution is to bring all your data together in one place, called a data lake. Use AWS tools like S3 and Glue to pull information from all your different systems (like your sales software, website, and warehouse) and bring it together.